Anyone who’s been to a Royal Television Society awards ceremony will be familiar with the work of Scottish firm, Midton Acrylics, makers these past 30 years of the Society’s much-coveted and distinctive trophies.

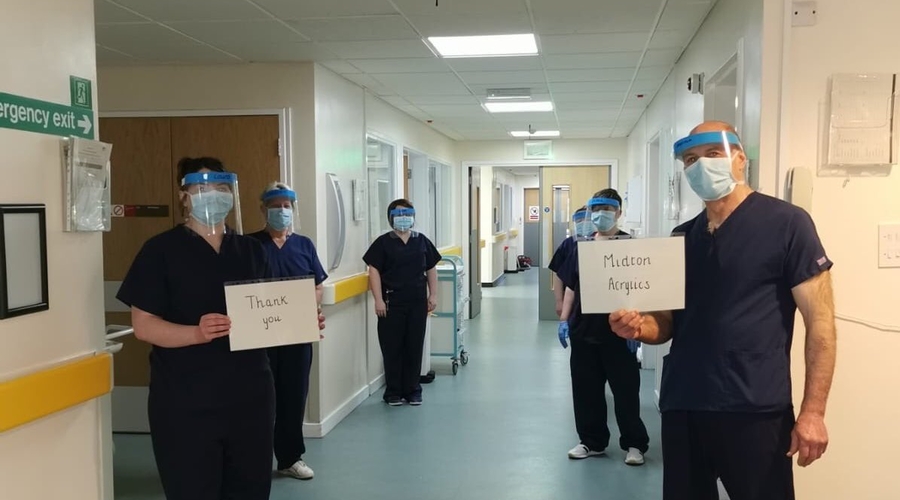

As the coronavirus crisis deepens, Midton has swapped making trophies for glamorous awards nights to manufacturing plastic visors to help protect doctors and nurses treating local Covid-19 patients.

The company is producing up to 600 visors a day from its factory based in Lochgilphead, Argyll.

The visors have been sent to Oban’s Lorn and the Islands Hospital and Mid Argyll Community Hospital in Lochgilphead – and may soon be arriving at hospitals in Glasgow.

“We wanted to do something to help the local community,” explained Midton director Graham Smith. “There’s a massive shortage of Personal Protective Equipment. We’d seen the plastic shields that provides complete coverage of the face on the news and thought we could make them quite easily from the stock we had in the factory.”

A volunteer team of eight workers are working for free at Midton, whose factory was re-opened on April 1 to make the visors following the lockdown and staff being furloughed.

Within 24 hours, Midton had created three prototypes before settling on a final version.

The shields are being donated free and financed by a crowdfunding campaign that has seen local businesses and individuals raise £5,500 in a fortnight.

“We reached our original target in hours,” said Smith. “The local community has been amazing.”

An appeal helped source more of the plastic and elastic required to produce the visors. “People have been dropping them in at the factory gate,” he added.

The aim is to make around 20,000 visors a month – and possibly 30,000 provided enough funding is forthcoming.

With demand for PPE soaring Midton plans to soon start manufacturing face masks and has also offered to make parts for ventilators.

“We’re looking at going into production on 3D-printed face masks,” said Smith. “Care homes are desperate for PPE. Ambulance crews and pharmacies need protecting as well.

“We were talking about drawing a line under it because we need to get back to opening the factory again and making awards, but we’re looking at how we can continue making PPE alongside our other activities.

“No one knows how long this is going to go on for, but I would say several months. We couldn’t just sit and watch this crisis unfold on the news.

“We had to do something to help people, especially when we saw local hospitals struggle with the lack of P P Equipment.”

Find out more about Midton Acrylics here: midton.com